FES-EZFW scale 1:4.0 wheel 90 mm

FES-EZFW scale 1:4.0 wheel 90 mm

incl. VAT. Shipping will be charged at checkout

Availability for pickups could not be loaded

- Delivery time: 7-9 days

- Made in Germany

- Consultation under +49 (0)6346-9893602

Do you have further questions? Write me an e-mail to mail@wemo-ezfw.de

WEMO-EZFW GmbH

Hohlgasse 1

76857 Gossersweiler-Stein

E-Mail: mail@wemo-ezfw.de

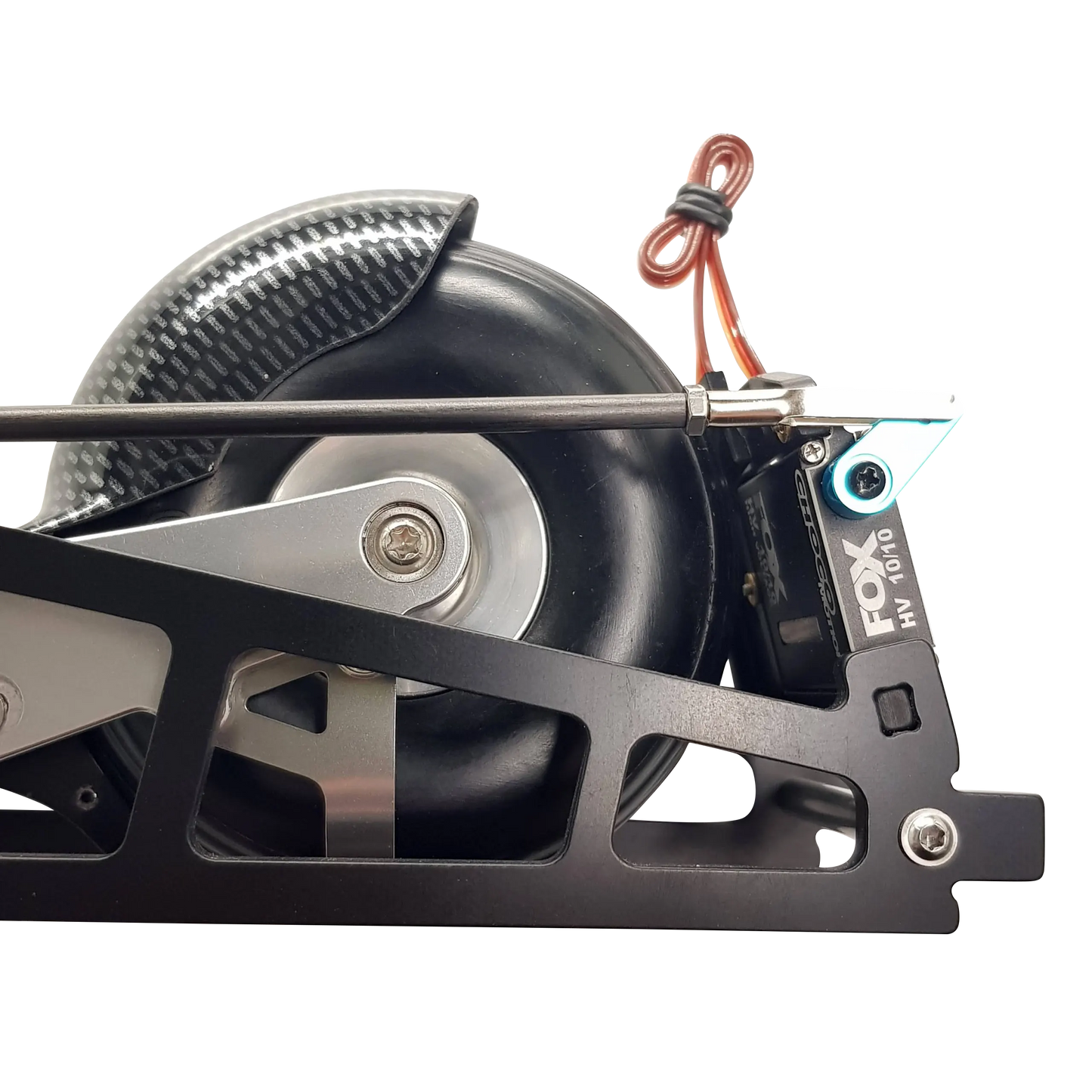

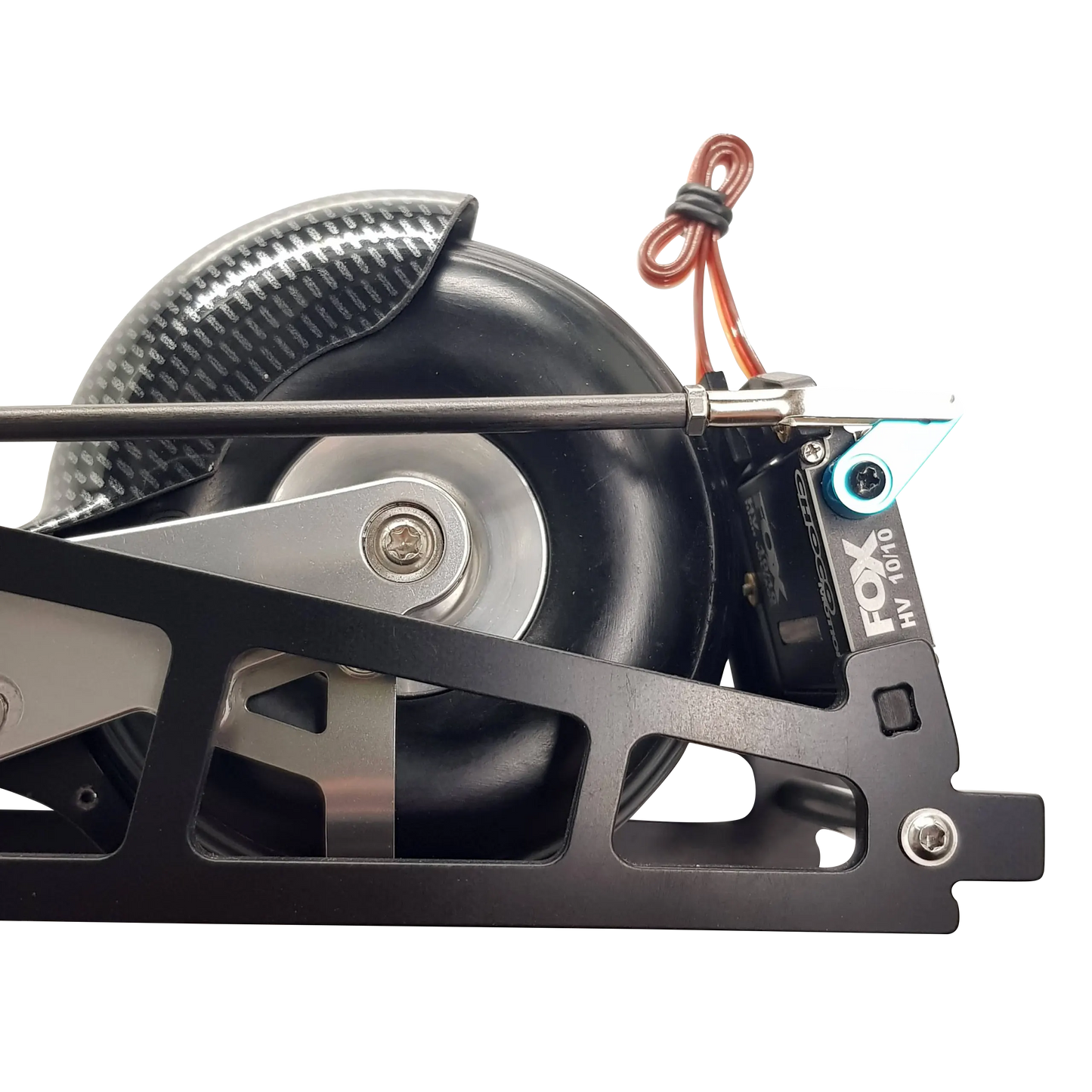

FES-EZFW scale 1:4.0 with wheel 90 mm

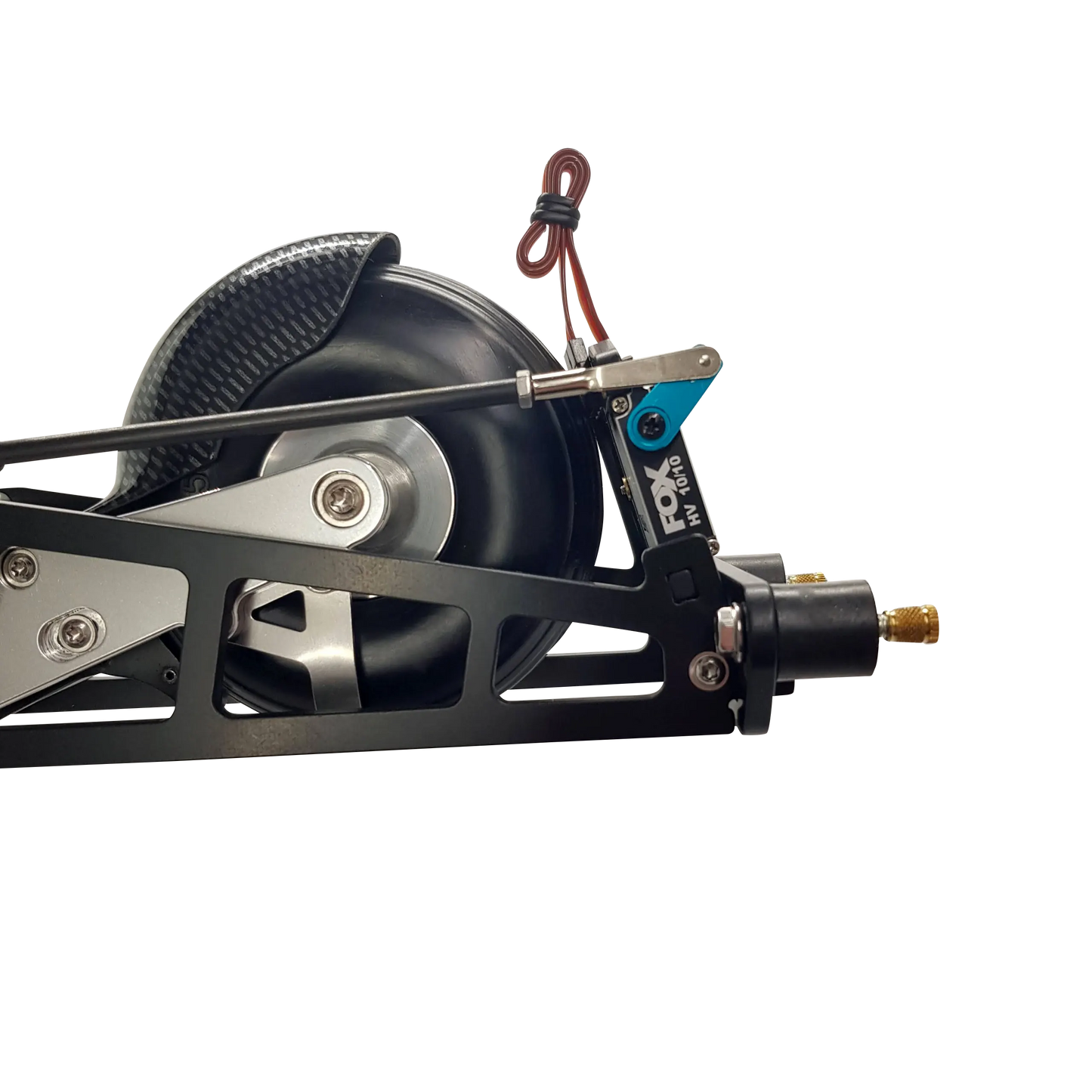

Since there are only a few landing gears available on the market for this scale, we took on the issue and designed a light but stable retractable landing gear. In order to achieve the ground clearance required for FES drives, the steering knuckles have been lengthened by 30 mm.

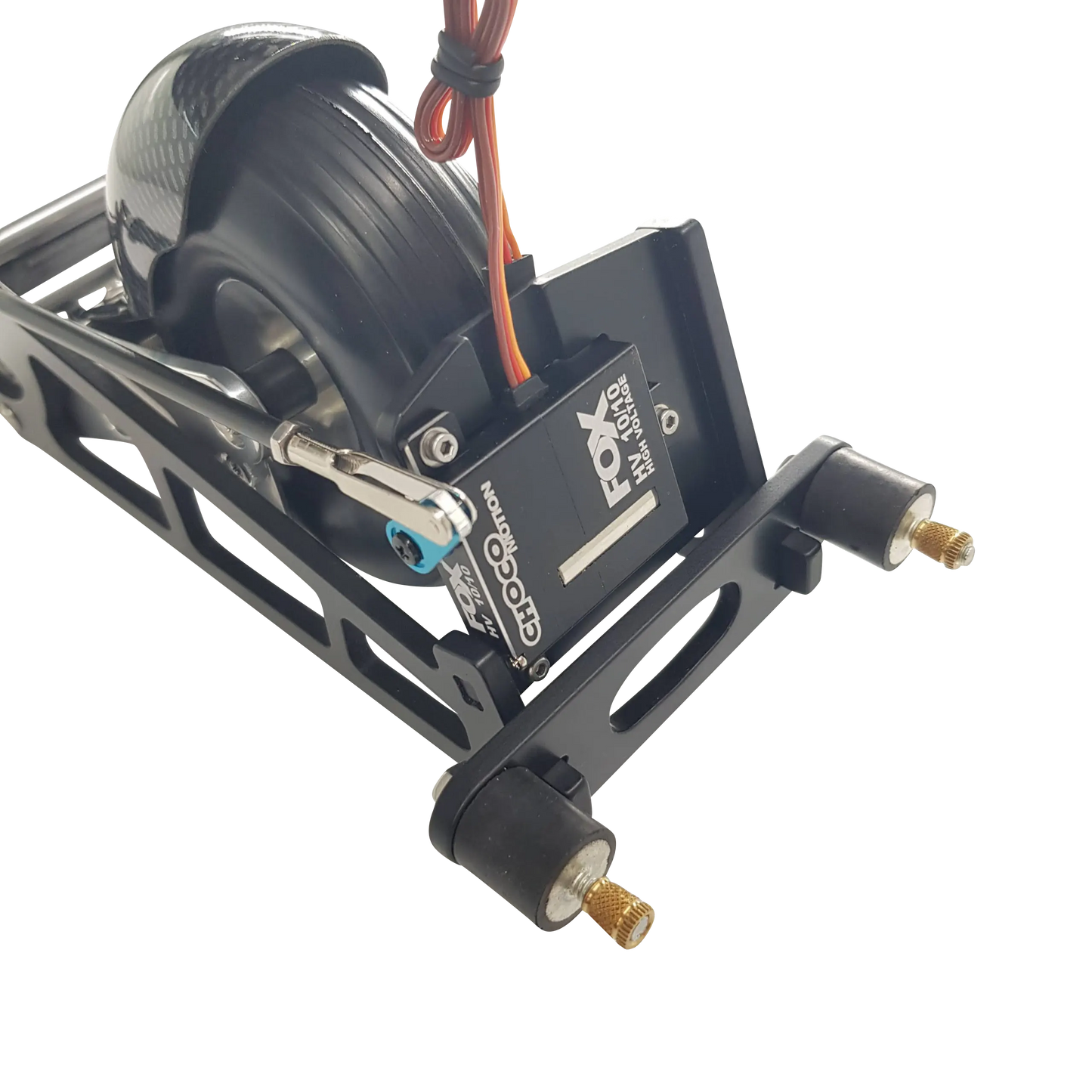

The side parts of the undercarriage on a scale of 1:4.0 with 90 mm wheels are made of 4.0 mm GRP (colored black). All milled edges are machined so that these parts do not pose a risk of injury and the feel is very comfortable.

The steering knuckles are made of 4.0 mm high-strength aluminum (AW 7075 T6) and are mirror-polished.

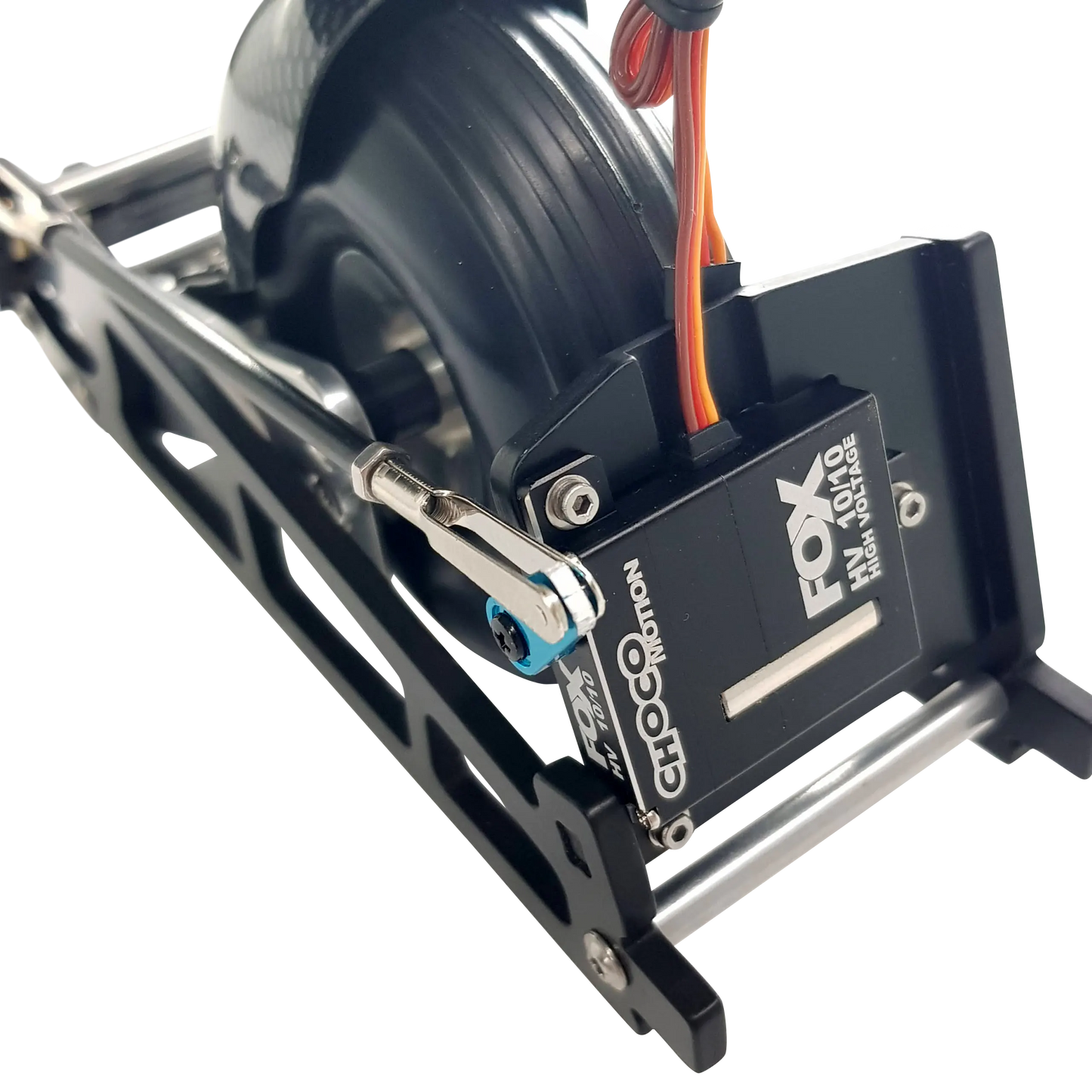

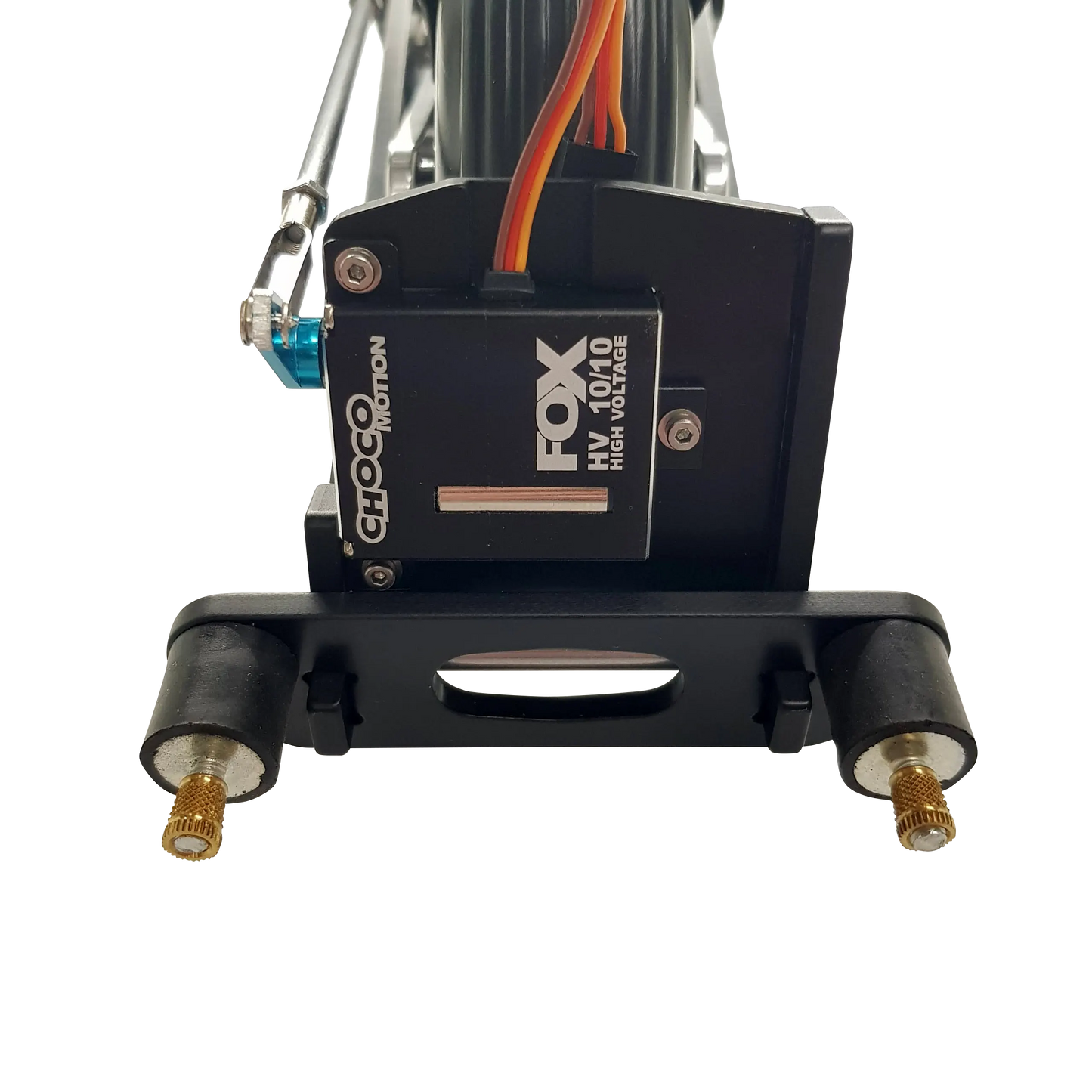

The attachment of the wheel drive servo is new: This is attached on the back between the side panels, which means that the servo wings on the side can be dispensed with. A 10 mm wing servo with 10 kg/cm torque at HV is used. The screw connections for M2 screws are pressed into the GRP as brass inserts.

Due to this design, the landing gear is very narrow and can be accommodated in any 1:4.0 scale fuselage.

Weight-optimized and shapely design through CNC-manufactured geometry. Due to the mechanical design, the wheel is firmly locked in the extended/retracted state. This means that the wheel cannot be extended by centrifugal forces, e.g. during a loop.

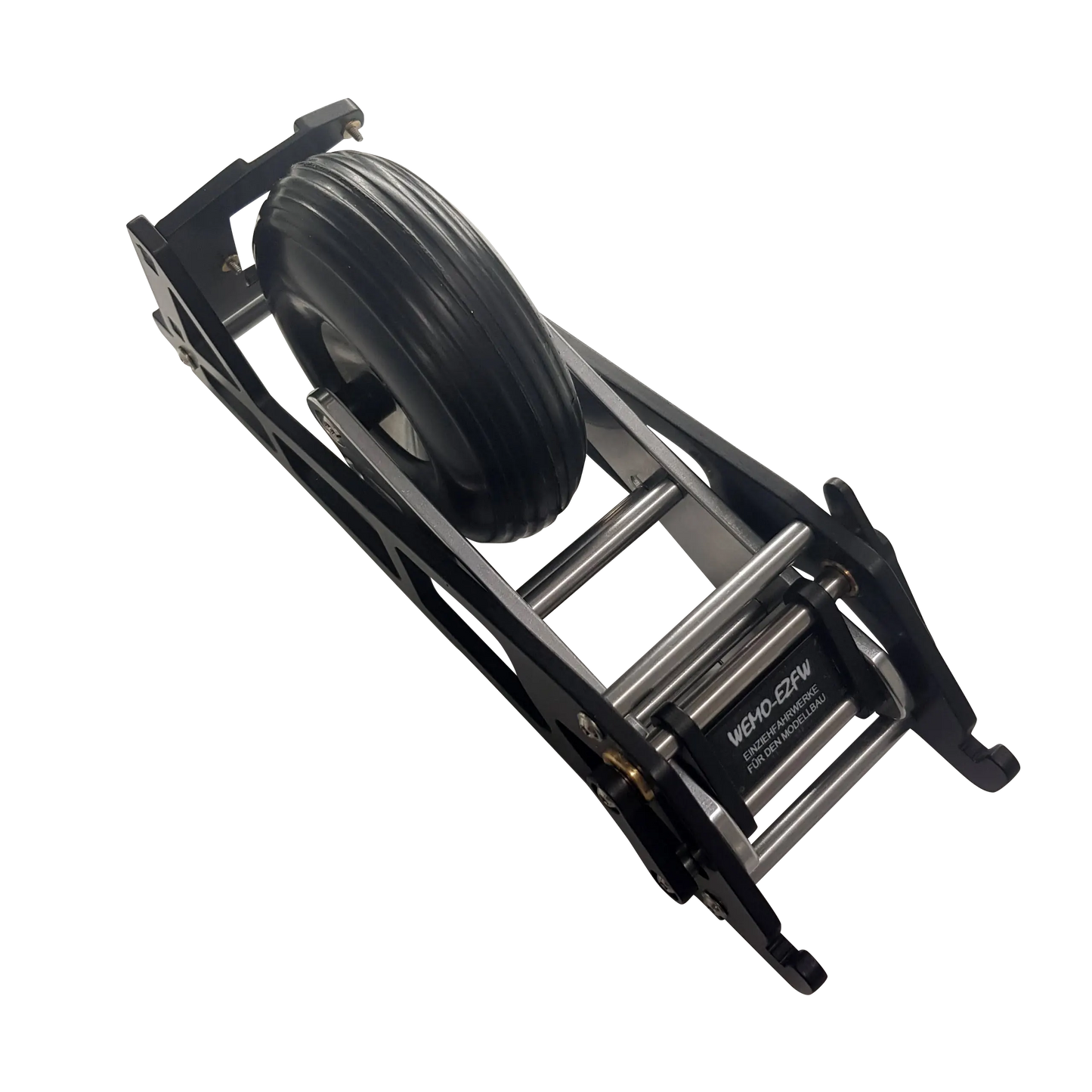

- The attachment in the glider is fixed between two frames or at the back together with the vibration rubber mount

- the landing gear is locked at the front with a cross brace in the main bulkhead

- the installation height of the EZFW in the fuselage is variable

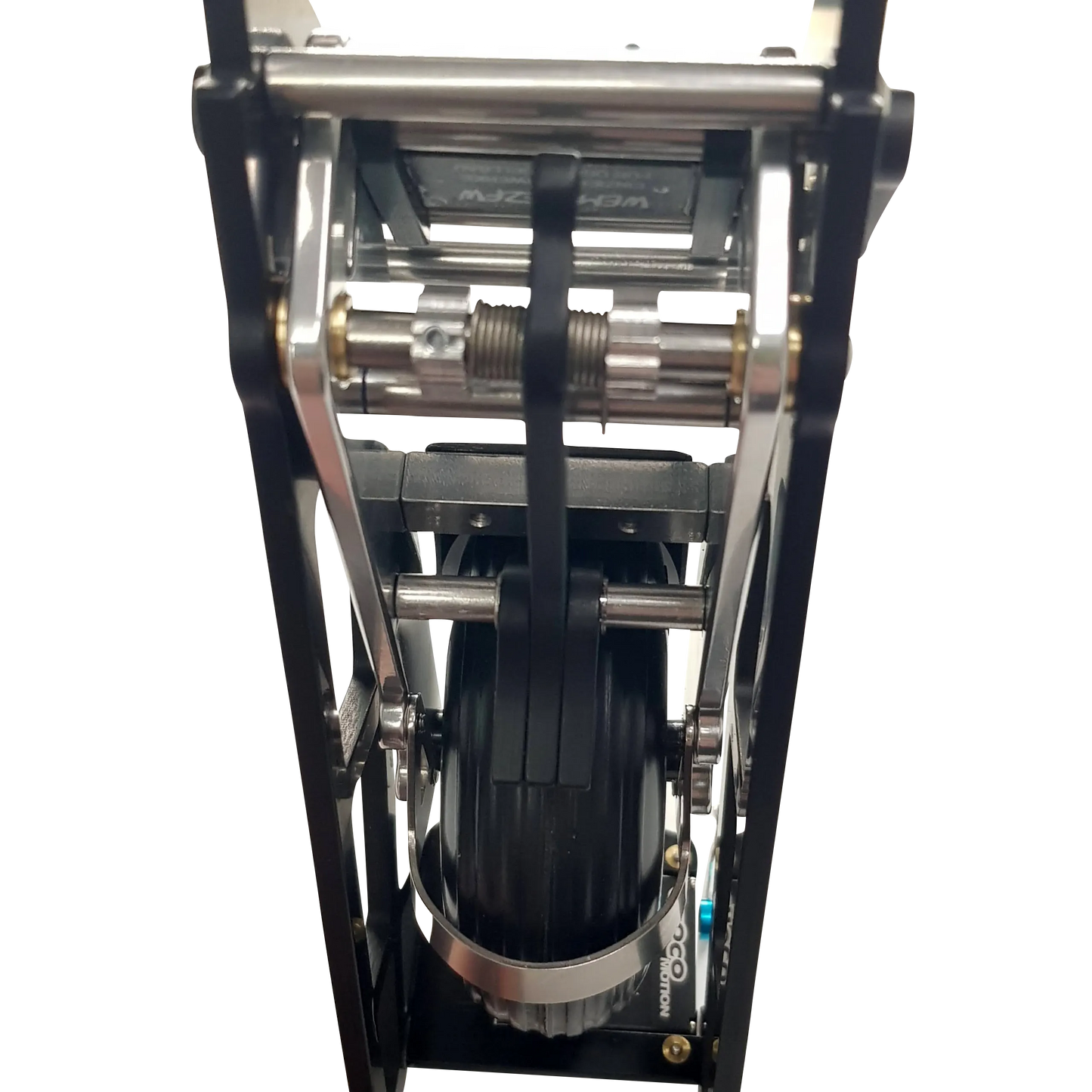

- the moving parts are mounted in brass bushings

The basic equipment consists of:

- the two side parts in 4.0 mm GRP / black

- the two swingarms in 4.0 mm high-strength aluminum (extended by 30 mm compared to the standard chassis)

- the required spacer bolt

- Servo mount for a 10 mm wing servo with drive-in nuts M2 and the appropriate screws

- the swivel mechanism incl. drive lever

- the required stainless steel screws

- 1 solid rubber wheel 90 mm with aluminum rim

All trolleys have a modular structure and can therefore be put together individually.

The following additional equipment for the chassis is optionally available:

- wheel cover

- Radbügel

- wheel shoe brake (the servo for actuating the brake is outsourced in front of the main frame and it is pulled with a cord)

- Linkage with two M3 clevises and a CFRP tube over the M3 threaded rod

- Shock-absorbing rubber mounting at the rear with small shock-absorbing rubbers with a diameter of 15 mm and M4 connection

Weight: the chassis weighs in the standard equipment 339 grams, fully equipped 441 grams. We deliberately accepted a few grams more weight here in favor of a very stable and durable chassis.

OR: We have now also designed this chassis size in such a way that you can use anti-vibration rubber mounts at the rear. For this purpose, the recess for the fastening clip has been changed on the front. This attachment now allows the undercarriage to move about 30 mm upwards on the rear side, so that the anti-vibration rubber mounts can work. If the anti-vibration pads are not used and the landing gear is installed firmly between two frames, the GRP clip fixes the landing gear firmly in the frame at the front.

A notice: on some pictures the chassis can be seen in full equipment. Reference is made to the above scope of delivery.

Unsere Partner

Mehr Inspiration gesucht?

Folgen Sie uns auf Social Media und erhalten Sie alle Neuigkeiten zu unseren Produkten.

Zu FacebookZu Youtube