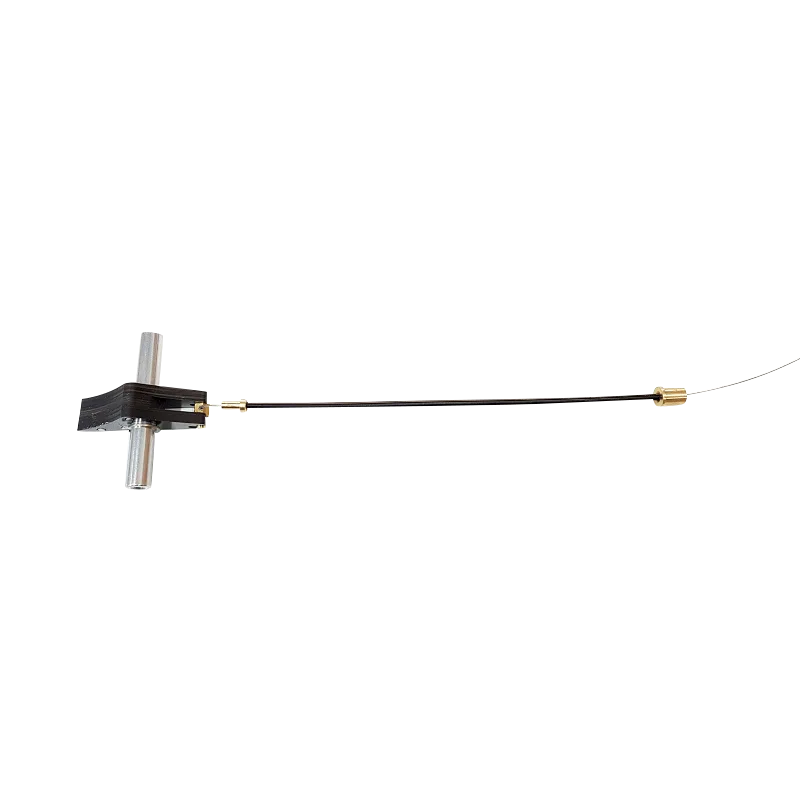

Wheel shoe brake with Bowden cable for wheel 178 mm

Wheel shoe brake with Bowden cable for wheel 178 mm

incl. VAT. Shipping will be charged at checkout

Availability for pickups could not be loaded

- Delivery time: 1 - 3 days

- Made in Germany

- Consultation under +49 (0)6346-9893602

Do you have further questions? Write me an e-mail to mail@wemo-ezfw.de

WEMO-EZFW GmbH

Hohlgasse 1

76857 Gossersweiler-Stein

E-Mail: mail@wemo-ezfw.de

We have functionally revised the proven wheel shoe brake.

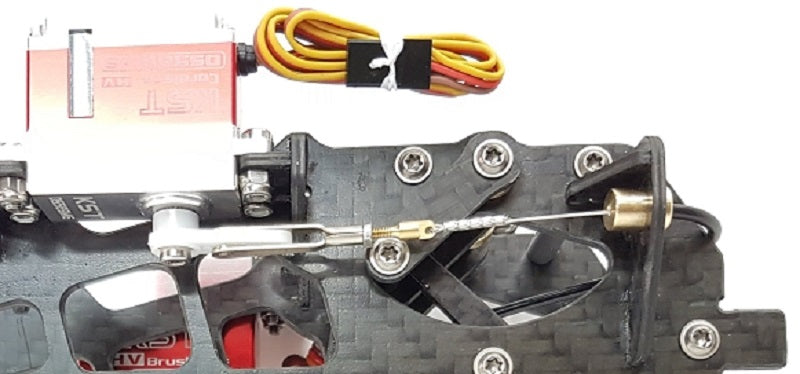

The brake is no longer linked via a reversing lever and a cable, but a Bowden cable with a steel cable is used. The Bowden cable is very thin (2.7 mm) and is highly flexible.

The steel cable has a tensile strength of 80 Kg. The Bowden cable has two abutments, these are attached to the chassis in standard brackets. The connection to the brake servo is made via an M3 fork head. The brake is fully assembled when delivered and only needs to be attached to the servo arm of the brake servo.

The advantage of the brake is that the Bowden cable is always the same length, lengthening the rope and fiddly tying a knot of the right length are no longer necessary. This type of linkage results in a very stiff linkage for the brake, which can actually transfer the power of the servo to the brake shoe.

The brake shoe is milled from CFRP and is attached to the axle with two snap rings. With all our chassis, the axis can be moved up and down via a slot in the steering knuckle. In this way you can react to tire wear and set the distance between the brake shoe and the tire precisely.

Weight: 27 grams

DANGER: The brake can only be used with our undercarriages. It is not suitable for retrofitting to chassis from other manufacturers.

Unsere Partner

Mehr Inspiration gesucht?

Folgen Sie uns auf Social Media und erhalten Sie alle Neuigkeiten zu unseren Produkten.

Zu FacebookZu Youtube